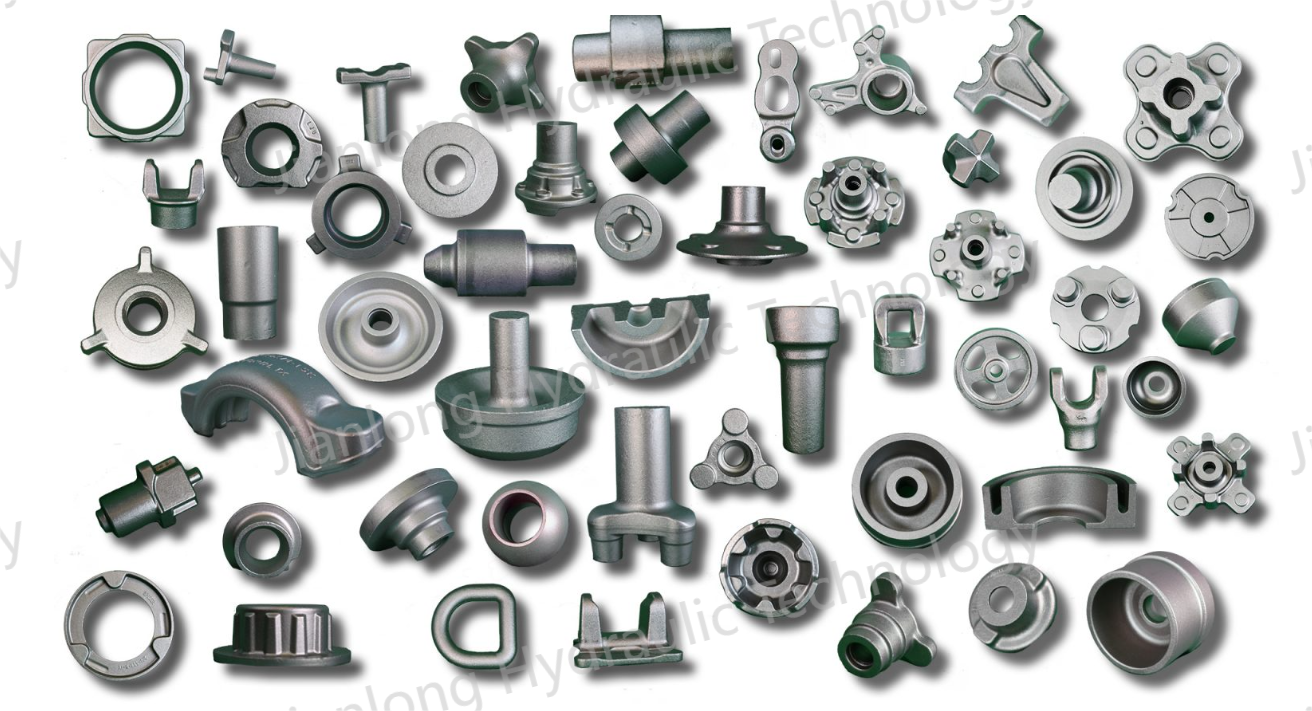

Today, we further explore the application of cold extrusion process in the field of hydraulic machinery. As the name implies, cold extrusion process is an advanced metal plastic processing technology, that is, by applying high pressure to the metal blank at room temperature or near room temperature, it causes plastic deformation in the mold cavity to obtain parts with the desired shape, size and performance. Over the years, this technology has become increasingly popular in the manufacturing industry, mainly because it can be used to produce a variety of products and large-scale production. Below, the Jianlong Hydraulic Technology Team will briefly introduce the cold extrusion process, and you are welcome to discuss it together.

1. Process principle

1.1 Cold deformation: Processing below the recrystallization temperature (usually room temperature), the metal grains are elongated or broken to form a fibrous structure, thereby improving strength and hardness.

1.2 Three-dimensional compressive stress: The blank is strongly extruded in the mold, and the internal stress state is mainly compressive stress, which is conducive to improving the plasticity of the metal (compared with tensile stress).

2. Process characteristics

2.1 Advantages:

2.1.1 High material utilization rate (up to 70%~90%), no chip waste

2.1.2 High processing accuracy (IT8~IT9 level), low surface roughness (Ra 1.6~0.2μm).

2.1.3 Strengthening workpiece: Cold work hardening effect improves the strength, hardness and fatigue life of parts.

2.1.4 Suitable for mass production, high efficiency (up to dozens of pieces per minute).

2.2 Disadvantages:

2.2.1 Large deformation resistance, high tonnage press required (up to 2000 tons or more).

2.2.2 High mold requirements: high-strength materials (such as cemented carbide) and precision processing are required.

2.2.3 The blank needs to be softened annealed and surface lubricated (such as phosphating, saponification).

3. Basic classification

3.1 Forward extrusion: The metal flow direction is the same as the punch movement direction, used to manufacture shaft and rod parts.

3.2 Reverse extrusion: The metal flow direction is opposite to the punch movement direction, suitable for the production of cup-shaped parts (such as shells, cartridge cases).

3.3 Compound extrusion: Combination of forward extrusion and reverse extrusion for complex shaped parts.

3.4 Radial extrusion: Metal flows radially to manufacture parts with flanges such as gears and flanges.

4. Typical application areas

4.1 Automotive industry: piston pins, wheel hub bolts, transmission shaft parts.

4.2 Electronics and electrical appliances: wiring terminals, capacitor housings.

4.3 Military and aerospace: shells, rocket engine parts.

4.5 Daily hardware: screws, nuts, knives.

Cold extrusion technology occupies an important position in modern manufacturing due to its high efficiency, material saving and high quality, and is especially suitable for the production of large-scale, high-performance metal parts. If you need high-quality hydraulic press manufacturing, please feel free to tell us (please scan the following WhatsApp QR code), Jianlong Hydraulic Technology will provide you with personalized, customized professional solutions and serve you wholeheartedly.

Contact: Jojo

Phone: 18822971180

E-mail: lifuyan78@gmail.com

Whatsapp:+8618822971180

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat