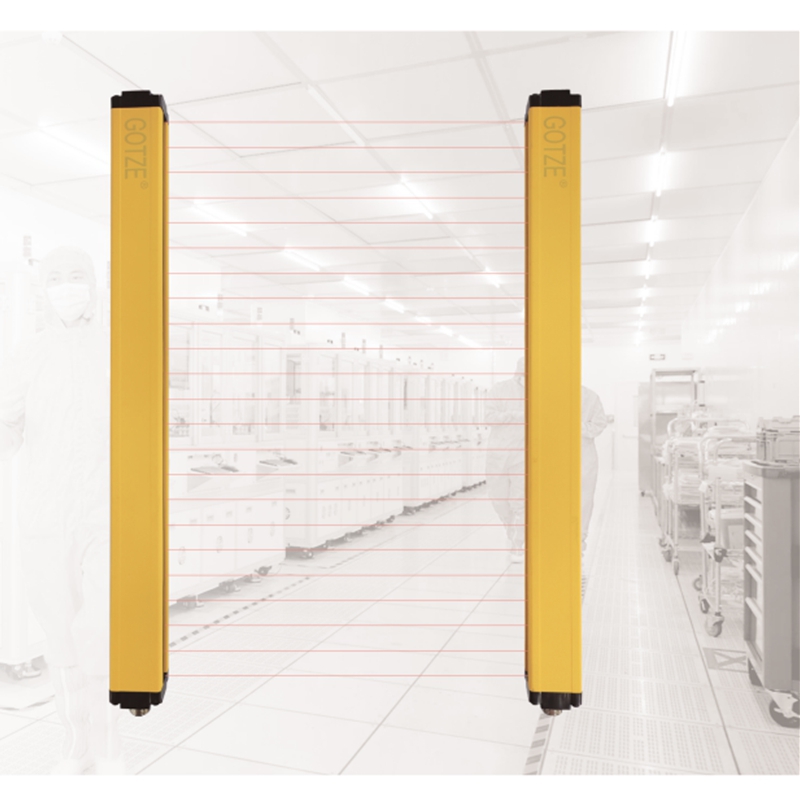

The use of safety light curtains (safety light curtains) in the hydraulic press industry is a key technology for ensuring operator safety and improving production efficiency. Due to the high operating pressures and rapid speeds of hydraulic presses, there are risks of mechanical injuries such as squeezing and shearing. Safety light curtains (safety light curtains) effectively prevent workplace accidents through non-contact detection. Below is a sharing from the editors of Jianlong Hydraulic Technology for your reference!

1. Core Application Scenarios

1.1 Mold Protection Area: Installed between the upper and lower molds of a hydraulic press, the light curtain detects an obstruction signal and immediately triggers a shutdown if an operator's hands or body enters the danger zone.

1.2 Feed/Reclaim Area: In automated production lines, light curtains monitor material inlet and outlet channels to ensure personnel do not stray into danger zones.

1.3 Multi-station Collaborative Protection: Large hydraulic presses may be equipped with multiple sets of light curtains to cover different danger points (e.g., multiple entrances at the front, back, left, and right sides). 2. Technical Requirements for Safety Light Curtains

2.1 Safety Level: Must comply with IEC 61496-1/2 standards to ensure high reliability.

2.2 Resolution Selection

2.3 Finger Protection: Beam spacing ≤ 14mm (prevents fingers from passing through).

2.4 Palm or Body Protection: Beam spacing ≤ 30mm.

2.5 Response Time: Typically ≤ 20ms, compatible with the hydraulic press's braking system to ensure a stop before the slide descends.

2.6 Interference Immunity: Must withstand oil, vibration, and electromagnetic interference from the hydraulic system (e.g., using a metal housing or fiber optic technology).

3. Integration with the Hydraulic Press System

3.1 Hard-wired Safety Circuit: The light curtain signal is directly connected to the hydraulic press's safety relay (e.g., PILZ or SICK brands), which disconnects the main control power supply or triggers an emergency stop. 3.2 Interlock Control: Communicates with the hydraulic press PLC to enable mode switching (e.g., the light barrier can be disabled in maintenance mode, but requires an authorized key or password).

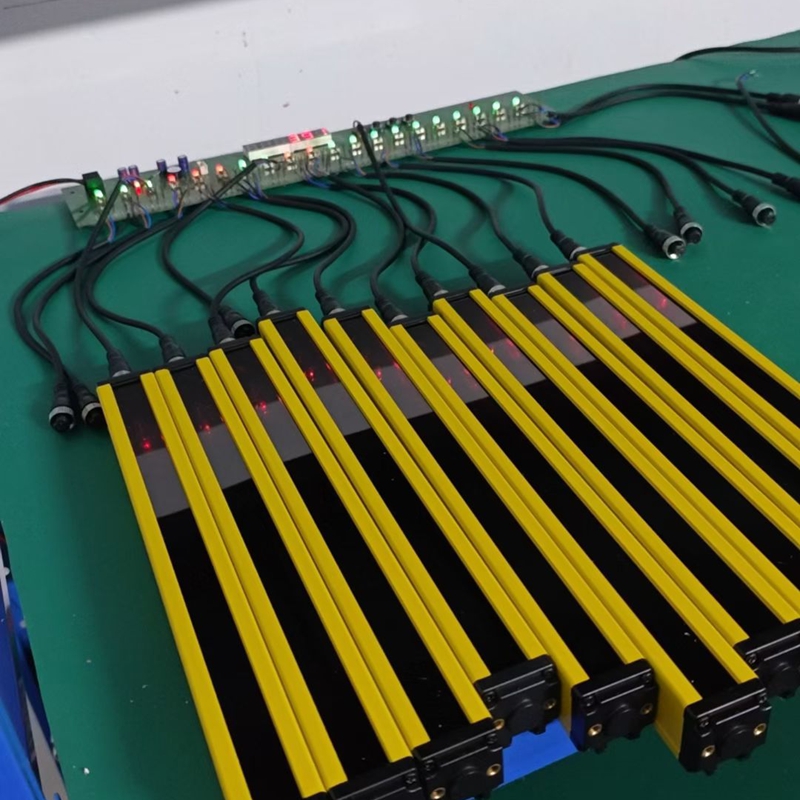

3.3 Dual-Circuit Design: Redundant detection channels prevent single-point failures from causing protection failures.

4. Key Application Cases

4.1 Automotive Parts Stamping: Install four light barriers around a four-column hydraulic press, coupled with a two-hand start button (requires simultaneous pressing of both hands to initiate operation).

4.2 Sheet Metal Processing: Use programmable light barriers (such as the SICK C4000) to distinguish between workpiece obstruction and human intrusion, reducing false shutdowns.

4.3 Maintenance Mode: Temporarily disable the light barrier via a key switch, but activate the hydraulic press's low-speed mode (<10 mm/s).

5. Future Trends

5.1 Intelligent Light Barriers: Integrated AI algorithms distinguish between personnel and materials, reducing false triggering.

5.2 Wireless: Simplifies installation, suitable for retrofitting older equipment.

5.3 IoT Integration: Real-time monitoring of light barrier status for predictive maintenance.

In short, safety light curtains (safety light screens) are a rigid requirement in the hydraulic press industry. Proper selection, installation, and regular maintenance can significantly reduce accident risks. Companies should consider their deployment based on specific equipment parameters and process requirements. For more information on safety light curtains, safety light curtains, and infrared sensors, or to purchase high-quality hydraulic presses, please feel free to contact us (scan the WhatsApp QR code below). Jianlong Hydraulic Technology will provide you with personalized, customized professional solutions and is dedicated to serving you.

Contact: Jojo

Phone: 18822971180

E-mail: lifuyan78@gmail.com

Whatsapp:+8618822971180

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat