The main application scenarios of frame-guide-type cold (hot) forging presses are very clear. They are core equipment almost exclusively designed for the modern manufacturing of high-performance, high-volume, precision metal parts. Their high rigidity, high precision, and high stability determine their primary application in fields with extremely high requirements for product quality and consistency. Below are their most core application scenarios, with the automotive industry holding a dominant position. Let's take a look at the main application scenarios of this machine, shared by Jianlong Hydraulic Technology.

1. Main Application Scenarios

1.1 Automotive Manufacturing Industry (The Core of the Core)

Automotive parts require extremely high strength, fatigue life, and dimensional consistency, and the demand is enormous. This is precisely the stage where frame-guide-type forging presses can demonstrate their advantages.

1.1.1 Powertrain System

◦ Connecting Rod: The core moving part of the engine, subjected to alternating stress, must be precision forged to ensure its streamlined fibrous structure and internal quality.

◦ Crankshaft: The "backbone" of the engine, with a complex shape, bearing enormous torsional and bending stresses; precision forging is the mainstream manufacturing process.

◦ Camshaft: Controls valve opening and closing, requiring high precision and wear resistance.

◦ Balance Shaft: Used to counteract engine vibration.

1.1.2 Transmission System

◦ Gearbox gears, synchronizer hubs/rings: These are key meshing components of the transmission system. Cold forging can produce toothed parts with high precision, good surface finish, and little or no machining, resulting in extremely high efficiency.

◦ Driveshafts, universal joints: Require high strength and durability.

1.1.3 Chassis and Safety Components

◦ Wheel hub bearing units: Related to driving safety, requiring high strength and dimensional stability.

◦ Ball joints, tie rods: Key connecting components in steering and suspension systems, subjected to impact and wear.

◦ Braking system components (e.g., pistons).

1.2 Aerospace Industry

This field has extremely demanding material performance requirements, extensively using high-strength aluminum alloys, titanium alloys, high-temperature alloys, and other difficult-to-deform materials.

1.2.1 Applications: Engine turbine disks, blades, casings, door connectors, landing gear components, etc.

1.2.2 Process Characteristics: Primarily employs hot forging or isothermal forging, where the poorly fluid metal is filled into the die at a constant temperature, forging high-performance forgings with complex shapes and uniform microstructure. This ensures the rigidity and precision of the frame machine.

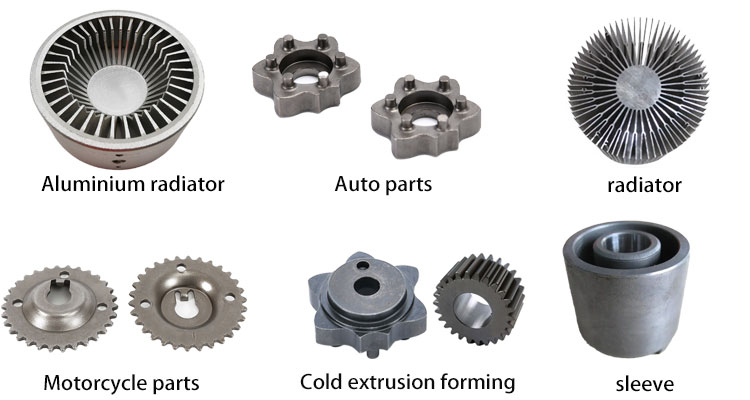

1.3 Standard Parts and Tools Industry

1.3.1 High-Strength Fasteners: Such as automotive engine bolts, wheel bolts, aerospace bolts, etc. These bolts have high strength grades (e.g., 10.9, 12.9), and cold forging processes can produce high-strength, fatigue-resistant, and streamlined fibers.

1.3.2 High-Performance Hand Tools: Such as wrenches, sockets, etc., forging processes ensure their durability and load-bearing capacity.

1.4 Other General Machinery and Home Appliance Industries

1.4.1 Compressor Components: Pistons, connecting rods, etc., for air conditioner and refrigerator compressors.

1.4.2 Hydraulic components: pump bodies, valve cores, etc.

1.4.3 Agricultural and construction machinery: wear-resistant parts such as track links and tooth blocks.

2. Why must frame-guided forging presses be used in these scenarios?

In summary, frame-guided forging presses must be used when the manufacturing of parts meets one or more of the following characteristics:

2.1 Difficult-to-deform materials

such as high-strength steel and titanium alloys, requiring enormous pressure and equipment rigidity.

2.2 Complex part geometry and high precision requirements

such as the tooth profile of gears, requiring extremely high motion accuracy and centering of the equipment to ensure accurate mold closing.

2.3 Multi-station forging

When multiple processes (such as punching, extrusion, and shaping) are completed on a single press, the slide block and mold will be subjected to asymmetrical off-center loads. Only a frame-guided structure can effectively resist such off-center loads.

2.4 Pursuing extremely high material utilization and production efficiency

Precision forging (especially cold forging) is a near-net-shape forming technology, saving materials and subsequent machining time, making it suitable for mass production.

2.5 High requirements for the mechanical properties and lifespan of parts

Forging processes can refine metal grains, forming continuous fibrous flow lines, significantly improving the strength, toughness, and fatigue life of parts.

Frame-guided cold (hot) forging presses are not general-purpose equipment, but rather "specialized tools" serving high-end manufacturing industries. Through one or several forming processes, they can produce high-performance, dimensionally precise "basic components," which form the "skeleton" of modern industrial equipment, especially in automobiles and aerospace vehicles. For more information/advice on frame-guided cold (hot) forging presses or to purchase other high-quality hydraulic presses, please contact us (or scan the WhatsApp QR code below). Jianlong Hydraulic Technology will provide you with personalized, customized professional solutions and is dedicated to serving you.

Contact: Jojo

Phone: 18822971180

E-mail: lifuyan78@gmail.com

Whatsapp:+8618822971180

Add: Guangyi Industrial Park, No.2 Jinfu West Road, Tanglip, Liaobu Town, Dongguan City, Guangdong Province, China

We chat